| Article No. | DN | PN (bar) | L (mm) | weight (kg) | Availability | watchlist |

|---|---|---|---|---|---|---|

| 1504007000 | 1 1/2" | 16 | 210 | 11.000 | on demand | |

| 1504008000 | 2" | 16 | 210 | 11.000 | on demand | |

| 1504040000 | 40 | 16 | 200 | 15.750 | on demand | |

| 1504050000 | 50 | 16 | 230 | 16.250 | on demand | |

| 1504065000 | 65 | 16 | 290 | 21.300 | on demand | |

| 1504080000 | 80 | 16 | 310 | 27.400 | on demand | |

| 1504080025 | 80 | 25 | 310 | 28.000 | on demand | |

| 1504100000 | 100 | 16 | 350 | 35.400 | on demand | |

| 1504125000 | 125 | 16 | 400 | 51.500 | on demand | |

| 1504150000 | 150 | 16 | 480 | 76.000 | on demand | |

| 1504200000 | 200 | 10 | 600 | 114.600 | on demand | |

| 1504200016 | 200 | 16 | 600 | 114.600 | on demand | |

| 1504250000 | 250 | 10/16 | 730 | 247.000 | on demand | |

| 1504300000 | 300 | 10/16 | 850 | 356.000 | on demand |

DN

watchlist

| 1504007000 | 1 1/2" | |

| PN | 16 bar | |

| L | 210 mm | |

| weight | 11.000 kg | |

| Availability | on demand | |

| 1504008000 | 2" | |

| PN | 16 bar | |

| L | 210 mm | |

| weight | 11.000 kg | |

| Availability | on demand | |

| 1504040000 | 40 | |

| PN | 16 bar | |

| L | 200 mm | |

| weight | 15.750 kg | |

| Availability | on demand | |

| 1504050000 | 50 | |

| PN | 16 bar | |

| L | 230 mm | |

| weight | 16.250 kg | |

| Availability | on demand | |

| 1504065000 | 65 | |

| PN | 16 bar | |

| L | 290 mm | |

| weight | 21.300 kg | |

| Availability | on demand | |

| 1504080000 | 80 | |

| PN | 16 bar | |

| L | 310 mm | |

| weight | 27.400 kg | |

| Availability | on demand | |

| 1504080025 | 80 | |

| PN | 25 bar | |

| L | 310 mm | |

| weight | 28.000 kg | |

| Availability | on demand | |

| 1504100000 | 100 | |

| PN | 16 bar | |

| L | 350 mm | |

| weight | 35.400 kg | |

| Availability | on demand | |

| 1504125000 | 125 | |

| PN | 16 bar | |

| L | 400 mm | |

| weight | 51.500 kg | |

| Availability | on demand | |

| 1504150000 | 150 | |

| PN | 16 bar | |

| L | 480 mm | |

| weight | 76.000 kg | |

| Availability | on demand | |

| 1504200000 | 200 | |

| PN | 10 bar | |

| L | 600 mm | |

| weight | 114.600 kg | |

| Availability | on demand | |

| 1504200016 | 200 | |

| PN | 16 bar | |

| L | 600 mm | |

| weight | 114.600 kg | |

| Availability | on demand | |

| 1504250000 | 250 | |

| PN | 10/16 bar | |

| L | 730 mm | |

| weight | 247.000 kg | |

| Availability | on demand | |

| 1504300000 | 300 | |

| PN | 10/16 bar | |

| L | 850 mm | |

| weight | 356.000 kg | |

| Availability | on demand | |

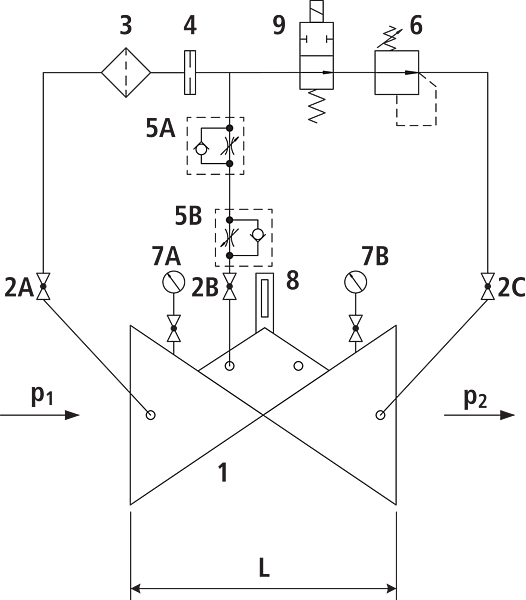

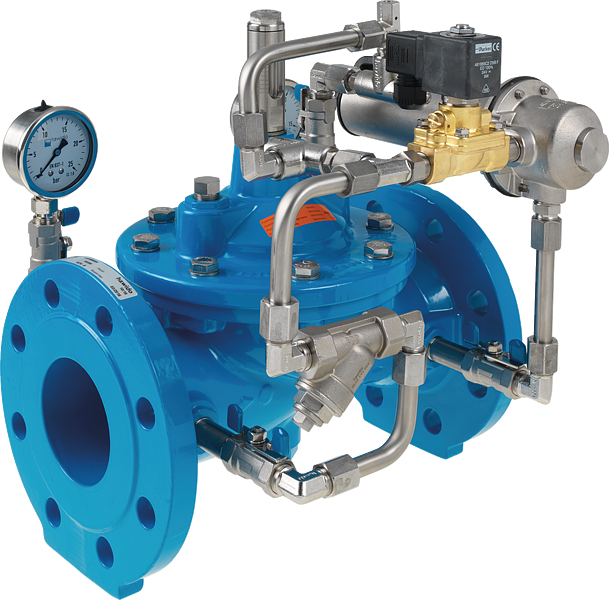

Physical characteristics

- The main valve is a hydraulically operating diaphragm valve. The work energy is the inherent medium.

- Most valve types operate purely hydraulically without any foreign energy.

Application

- To use in drinking water systems (other media after consultation)

- Reduction in pressure for a network feed with a reservoir as the water level control

- Controlled emergency feed into a second network (network connections)

- In combination with an orifice plate for filling the reservoir

Mode of operation

- The pressure-reducing valve for electrical actuation decreases a variable inlet pressure to a constant outlet pressure when the solenoid valve is de-energized. If the solenoid valve is energized, the valve is closed. Fluctuating inlet pressure and flow do not have any effect on the regulated outlet pressure. The outlet pressure can be adjusted within a range of 1,5 to 12 bar (standard edition). The speed of opening and closing can be set separately from each other.

Product information

- To calculate the dimensions of the valve please refer to the following information:

- Maximum and minimum inlet pressure (static and dynamic pressure ratios)

- Maximum and minimum flow rates

- Desired outlet pressure

- Possible requirement for extinguishing water

- Available line diameters and lengths

- Voltage information for the solenoid valve

- Construction of the valve (straight or angle design)

- For the calculation basis, information on the loss of pressure and the characteristic values of the valve, please refer to the end of Chapter E.

Design

- Design according to DIN EN 1074

- Construction length acc. to DIN EN 558

- Flange mass according to DIN 1092-2, to PN 25 DN 300

- Pressure levels: PN 10 or PN 16 to DN 300, PN 25 to DN 200, higher pressures on request.

- Nominal widths DN 50, DN 80, DN 100 and DN 150 available in angular design

- Nominal widths 1 ½" and 2" with threaded connection (female thread)

- Medium temperature up to 40°C

Installation and assembly

- Shut–off valves should be fitted on both sides of the valve and a dirt trap should be installed on the inlet side of the valve. Depending on the installation situation, a mounting/dismounting adapter and an aeration and ventilation system should be provided.

Vantages

- Maintenance-free, non-rusting valve seat

- Pressed-in seat

- EWS-coating according to RAL GSK

more