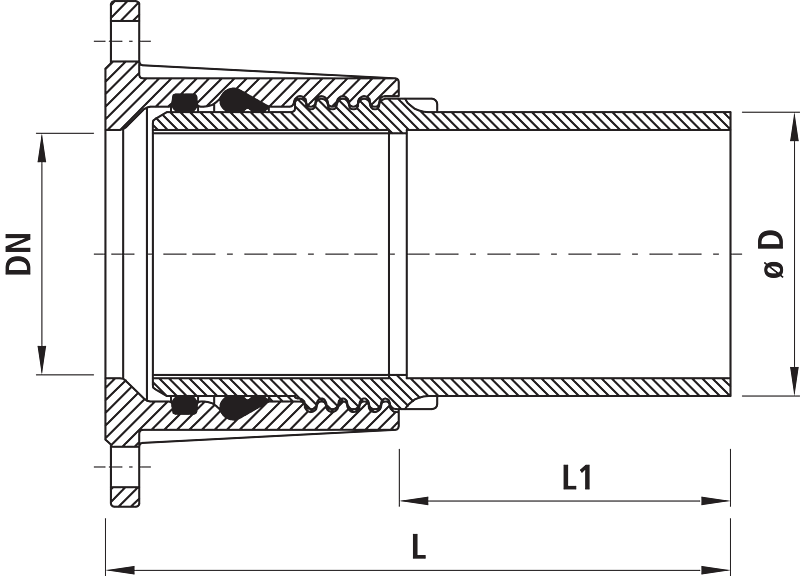

| Article No. | DN | ø D | PN (bar) | L (mm) | L1 (mm) | weight (kg) | NPK No. 411 | NPK No. 412 | Availability | watchlist |

|---|---|---|---|---|---|---|---|---|---|---|

| 3100080090 | 80 | 90 | 16 | 305 | 180 | 6.600 | 425257 | 425516 | ex warehouse | |

| 3100100110 | 100 | 110 | 16 | 325 | 185 | 9.400 | 425258 | 425527 | ex warehouse | |

| 3100100125 | 100 | 125 | 16 | 375 | 185 | 12.600 | 425259 | 425528 | ex warehouse | |

| 3100150160 | 150 | 160 | 16 | 360 | 185 | 18.000 | 425262 | 425542 | ex warehouse | |

| 3100150180 | 150 | 180 | 16 | 435 | 175 | 24.400 | 425263 | 425543 | ex warehouse | |

| 3100200200 | 200 | 200 | 10 | 405 | 195 | 28.600 | 425264 | 425554 | ex warehouse | |

| 3100201200 | 200 | 200 | 16 | 405 | 195 | 28.800 | 425264 | 425554 | ex warehouse | |

| 3100200225 | 200 | 225 | 10 | 405 | 195 | 30.000 | 425265 | 425555 | ex warehouse | |

| 3100201225 | 200 | 225 | 16 | 405 | 195 | 30.000 | 425265 | 425555 | ex warehouse |

DN

watchlist

| 3100080090 | 80 | |

| ø D | 90 | |

| PN | 16 bar | |

| L | 305 mm | |

| L1 | 180 mm | |

| weight | 6.600 kg | |

| NPK No. 411 | 425257 | |

| NPK No. 412 | 425516 | |

| Availability | ex warehouse | |

| 3100100110 | 100 | |

| ø D | 110 | |

| PN | 16 bar | |

| L | 325 mm | |

| L1 | 185 mm | |

| weight | 9.400 kg | |

| NPK No. 411 | 425258 | |

| NPK No. 412 | 425527 | |

| Availability | ex warehouse | |

| 3100100125 | 100 | |

| ø D | 125 | |

| PN | 16 bar | |

| L | 375 mm | |

| L1 | 185 mm | |

| weight | 12.600 kg | |

| NPK No. 411 | 425259 | |

| NPK No. 412 | 425528 | |

| Availability | ex warehouse | |

| 3100150160 | 150 | |

| ø D | 160 | |

| PN | 16 bar | |

| L | 360 mm | |

| L1 | 185 mm | |

| weight | 18.000 kg | |

| NPK No. 411 | 425262 | |

| NPK No. 412 | 425542 | |

| Availability | ex warehouse | |

| 3100150180 | 150 | |

| ø D | 180 | |

| PN | 16 bar | |

| L | 435 mm | |

| L1 | 175 mm | |

| weight | 24.400 kg | |

| NPK No. 411 | 425263 | |

| NPK No. 412 | 425543 | |

| Availability | ex warehouse | |

| 3100200200 | 200 | |

| ø D | 200 | |

| PN | 10 bar | |

| L | 405 mm | |

| L1 | 195 mm | |

| weight | 28.600 kg | |

| NPK No. 411 | 425264 | |

| NPK No. 412 | 425554 | |

| Availability | ex warehouse | |

| 3100201200 | 200 | |

| ø D | 200 | |

| PN | 16 bar | |

| L | 405 mm | |

| L1 | 195 mm | |

| weight | 28.800 kg | |

| NPK No. 411 | 425264 | |

| NPK No. 412 | 425554 | |

| Availability | ex warehouse | |

| 3100200225 | 200 | |

| ø D | 225 | |

| PN | 10 bar | |

| L | 405 mm | |

| L1 | 195 mm | |

| weight | 30.000 kg | |

| NPK No. 411 | 425265 | |

| NPK No. 412 | 425555 | |

| Availability | ex warehouse | |

| 3100201225 | 200 | |

| ø D | 225 | |

| PN | 16 bar | |

| L | 405 mm | |

| L1 | 195 mm | |

| weight | 30.000 kg | |

| NPK No. 411 | 425265 | |

| NPK No. 412 | 425555 | |

| Availability | ex warehouse | |

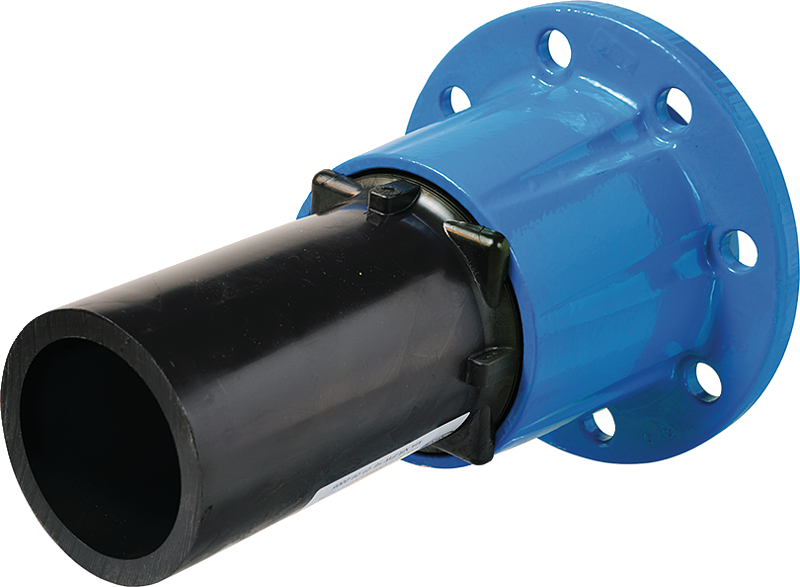

Characteristics

- Quick and easy installation

- Secure sealing

- Removable at any time

- Flange connection compound

- according to DIN EN 1092-2

- DN 25 to DN 150: PN 10 / 16

- DN 200 to DN 600: PN 10 or 16, specify when ordering - Operating temperature

- max. 40 °C

Material

- PE weld-on end: PE 100, SDR 11

- Bored to SDR 17, on request

- Spheroidal Cast Iron EN-GJS-400 (GGG 40)

- EWS coating according to GSK, RAL-GZ 662, layer thickness min. 250 μm

more