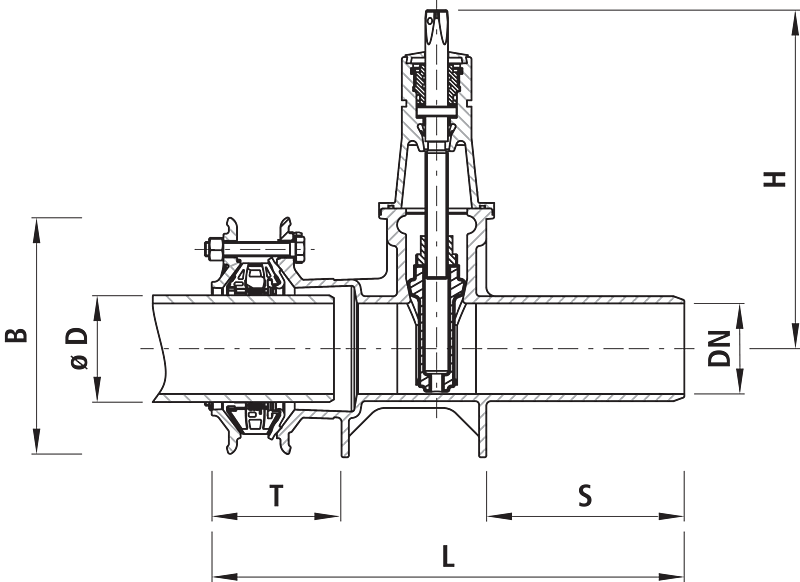

| Article No. | DN | ø D min./max. | PN (bar) | H (mm) | L (mm) | T min./max. | B (mm) | S | weight (kg) | NPK No. 412 | BIM / CAD | Availability | watchlist |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4251100000 | 100 | 104-132 | 16 | 343 | 550 | 119-136 | 260 | 220 | 27.000 | 811712 | ex warehouse | ||

| 4251125000 | 125 | 131-160 | 16 | 421 | 636 | 143-161 | 290 | 230 | 44.000 | 811713 | ex warehouse | ||

| 4251150000 | 150 | 155-192 | 16 | 433 | 580 | 126-143 | 350 | 235 | 49.000 | 811714 | ex warehouse | ||

| 4251200000 | 200 | 198-230 | 16 | 541 | 680 | 143-161 | 405 | 260 | 80.000 | 811715 | ex warehouse |

DN

watchlist

| 4251100000 | 100 | |

| ø D min./max. | 104-132 | |

| PN | 16 bar | |

| H | 343 mm | |

| L | 550 mm | |

| T min./max. | 119-136 | |

| B | 260 mm | |

| S | 220 | |

| weight | 27.000 kg | |

| NPK No. 412 | 811712 | |

| BIM-Data | https://www.cadenas.de/de/4251100000 | |

| Availability | ex warehouse | |

| 4251125000 | 125 | |

| ø D min./max. | 131-160 | |

| PN | 16 bar | |

| H | 421 mm | |

| L | 636 mm | |

| T min./max. | 143-161 | |

| B | 290 mm | |

| S | 230 | |

| weight | 44.000 kg | |

| NPK No. 412 | 811713 | |

| BIM-Data | https://www.cadenas.de/de/4251125000 | |

| Availability | ex warehouse | |

| 4251150000 | 150 | |

| ø D min./max. | 155-192 | |

| PN | 16 bar | |

| H | 433 mm | |

| L | 580 mm | |

| T min./max. | 126-143 | |

| B | 350 mm | |

| S | 235 | |

| weight | 49.000 kg | |

| NPK No. 412 | 811714 | |

| BIM-Data | https://www.cadenas.de/de/4251150000 | |

| Availability | ex warehouse | |

| 4251200000 | 200 | |

| ø D min./max. | 198-230 | |

| PN | 16 bar | |

| H | 541 mm | |

| L | 680 mm | |

| T min./max. | 143-161 | |

| B | 405 mm | |

| S | 260 | |

| weight | 80.000 kg | |

| NPK No. 412 | 811715 | |

| BIM-Data | https://www.cadenas.de/de/4251200000 | |

| Availability | ex warehouse | |

Application

- Crossover slider multigrade sleeve / spigot-end part incl. the proven E3 technology

- High tensile connection in multiple areas"SYNOFLEX" for all types of pipes

- The longer range coupling HAWLESYNOFLEX is the economical alternative to welding technology. It is used in the drinking water supply and waste water disposal. It is used for a shear-protected connection of all the customary types of pipes made from cast, steel, PE, and PVC or for connecting pipes with different external diameters, as well as in poor weather conditions in particular.

Shear protection is not guaranteed when using fiber cement pipes.

Characteristics

- Permissible angle up to max. 8° (+/-4° per socket)

- Flange connection compound

- according to EN 1092-2 - Operating temperature

- max. 40 °C - Pressure PN 16

Thrust protection

- High tensile connection in multiple areas for all types of pipes

- Spigot-end part for all plug-in sleeve systems with internal or external shearing protection

Material

- Housing

- Spheroidal graphite cast iron EN-GJS-400 (GGG 40)

- EWS coating according to GSK, RAL-GZ 662, coating thickness min. 250 μm - Seals

- EPDM - SYNOFLEX-Ring

- POM - Pull protection element

- Steel, protected against corrosion

- Mounted on every individual support element - Bolts

- greased for life

- with INOX antirotation lock

Caution

- For the fiber cement pipes tensile strength is not guaranteed.

- A supporting sleeve must be used without fail for high tensile connections of PE pipes.

- The maximum insertion depth must not be exceeded, in order to ensure a gap is maintained between the pipes or before the stop.

more