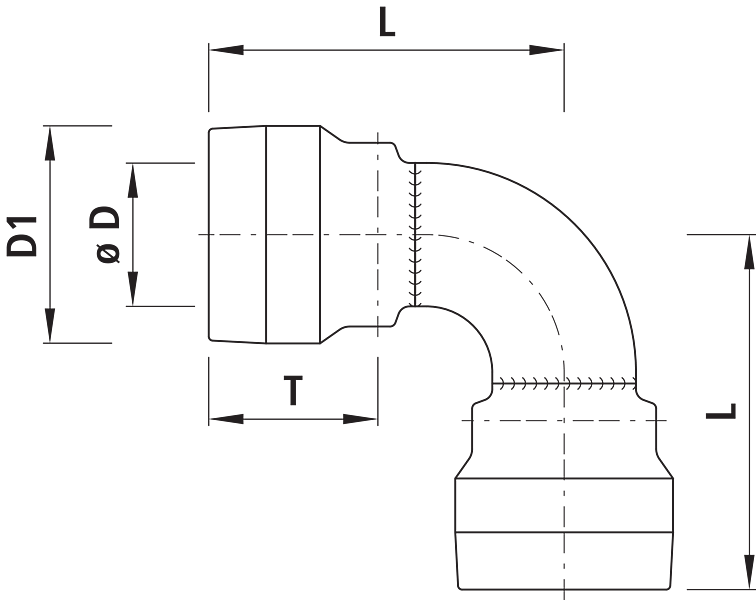

| Article No. | ø D / PE (mm) | PN (bar) | L (mm) | T (mm) | D1 (mm) | weight (kg) | NPK No. 411 | NPK No. 412 | Availability | watchlist |

|---|---|---|---|---|---|---|---|---|---|---|

| 7321110000 | 110 | 16 | 313 | 170 | 175 | 4.700 | 433118 | 451317 | assembly time | |

| 7321180000 | 180 | 16 | 443 | 211 | 255 | 13.300 | 433123 | 451323 | assembly time |

DN

watchlist

| 7321110000 | ||

| ø D / PE | 110 mm | |

| PN | 16 bar | |

| L | 313 mm | |

| T | 170 mm | |

| D1 | 175 mm | |

| weight | 4.700 kg | |

| NPK No. 411 | 433118 | |

| NPK No. 412 | 451317 | |

| Availability | assembly time | |

| 7321180000 | ||

| ø D / PE | 180 mm | |

| PN | 16 bar | |

| L | 443 mm | |

| T | 211 mm | |

| D1 | 255 mm | |

| weight | 13.300 kg | |

| NPK No. 411 | 433123 | |

| NPK No. 412 | 451323 | |

| Availability | assembly time | |

Application

- The HAWLE-GRIP connection was developed for the water supply to connect PE pipes SDR 11 or SDR 17 with a simple push-fit connection.

- The HAWLE-GRIP connection can also be used in the event of water running behind or in situations where the welding technique fails.

- The HAWLE-GRIP connection can be installed in a space-saving and de-energised manner.

- The HAWLE-GRIP connection is always used where the water pipe has to be put back into operation quickly and there is no time for the welding technique with cooling tim.

- The shear-resistant plug-in connection saves a lot of time and therefore money compared to welding technology.

Product information

- DN 250, DN 315, DN 355, DN 400 and DN 450 available on request

Characteristics

- Patented train protection system

- Flange connection compound

- according to EN 1092-2 - Operating temperature

- max. 40 °C - Pressure PN 16

- SGVW certified

Material

- Socket body

- Plastic PE 100 RC - Shear protection elements

- High-strength plastic

- Spring-mounted individual segmentsC - Lip seal

- EPDM/System 3S

more