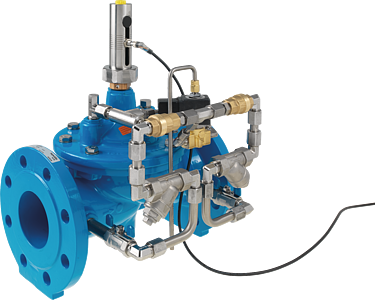

1705125000 Pump protection valve with mechanical non-return flap DN 125 PN 10/16

Components

- 1: Main valve

- 2: Ball valve (A, B)

- 3: Filter (A, B)

- 4: Throttle check valve

- 5: Electric solenoid valve

- 6: Check valve (A, B)

- 7: Mechanical non-return flap

- 8: Electric position indicator

- 9: Accessories (optional)

Add to watchlist

Product attributes

| DN | 125 |

|---|---|

| PN | 16 bar |

| L | 400 mm |

| weight | 52.000 kg |

| Availability | on demand |

Physical characteristics

- The main valve is a hydraulically operating diaphragm valve. The work energy is the inherent medium.

- Most valve types operate purely hydraulically without any foreign energy.

Application

- To use in drinking water systems (other media after consultation)

- Actuation of the valve with the pump control system

- Protection of the pump against overloading caused by a no–load operation

Mode of operation

- The pump protection valve opens with a time delay after the pump is started up. Consequently the network pressure increases to the full pump pressure before the valve opens. With a controlled stopping of the pump, the valve closes before the pump stops. The opening and closing speeds can be set on the throttle non–return valve. In the event of a power failure, the fitted mechanical non–return flap prevents the valve from closing too quickly and consequently a backflow to the pump.

Product information

- To calculate the dimensions of the valve please refer to the following information:

- Maximum and minimum inlet pressure (static and dynamic pressure ratios)

- Existing counterpressure

- Required flow rate, pump capacity

- Maximum permissible loss of pressure

- Voltage information for the solenoid valve

- Available line diameters and lengths

- Construction of the valve (straight or angle design)

- The controller is to be provided by the customer.

- For the calculation basis, information on the loss of pressure and the characteristic values of the valve, please refer to the end of Chapter E.

Design

- Design according to DIN EN 1074

- Construction length acc. to DIN EN 558

- Flange mass according to DIN 1092-2, to PN 25 DN 300

- Pressure levels: PN 10 or PN 16 to DN 300, PN 25 to DN 200, higher pressures on request.

- Nominal widths DN 50, DN 80, DN 100 and DN 150 available in angular design

- Nominal widths 1 ½" and 2" with threaded connection (female thread)

- Medium temperature up to 40°C

Installation and assembly

- The pump protection valve is installed in the feed pipe of the pipe. A shut–off valve is to be installed on the outlet side.

Vantages

- Maintenance-free, non-rusting valve seat

- Pressed-in seat

- EWS-coating according to RAL GSK

more