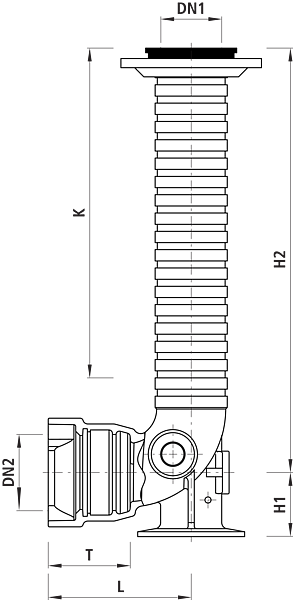

| Article No. | DN1 (mm) | DN2 (mm) | Outlet lateral left | Outlet lateral right | H1 (mm) | H2 (mm) | L (mm) | K | T (mm) | weight (kg) | NPK No. 411 | NPK No. 412 | Availability | watchlist |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N842100000 | 100 | 100 | 105 | 695 | 235 | 430 | 135 | 30.000 | 856365 | 853121 | ex warehouse | |||

| N842125000 | 100 | 125 | 105 | 695 | 235 | 430 | 145 | 32.000 | 856366 | 853122 | ex warehouse | |||

| N842100001 | 100 | 100 | 2" | 105 | 695 | 235 | 430 | 135 | 30.000 | assembly time | ||||

| N842100002 | 100 | 100 | 2" | 105 | 695 | 235 | 430 | 135 | 30.000 | assembly time | ||||

| N842125001 | 100 | 125 | 2" | 105 | 695 | 235 | 430 | 145 | 32.000 | assembly time | ||||

| N842125002 | 100 | 125 | 2" | 105 | 695 | 235 | 430 | 145 | 32.000 | assembly time |

DN

watchlist

| N842100000 | ||

| DN1 | 100 mm | |

| DN2 | 100 mm | |

| Outlet lateral left | ||

| Outlet lateral right | ||

| H1 | 105 mm | |

| H2 | 695 mm | |

| L | 235 mm | |

| K | 430 | |

| T | 135 mm | |

| weight | 30.000 kg | |

| NPK No. 411 | 856365 | |

| NPK No. 412 | 853121 | |

| Availability | ex warehouse | |

| N842125000 | ||

| DN1 | 100 mm | |

| DN2 | 125 mm | |

| Outlet lateral left | ||

| Outlet lateral right | ||

| H1 | 105 mm | |

| H2 | 695 mm | |

| L | 235 mm | |

| K | 430 | |

| T | 145 mm | |

| weight | 32.000 kg | |

| NPK No. 411 | 856366 | |

| NPK No. 412 | 853122 | |

| Availability | ex warehouse | |

| N842100001 | ||

| DN1 | 100 mm | |

| DN2 | 100 mm | |

| Outlet lateral left | 2" | |

| Outlet lateral right | ||

| H1 | 105 mm | |

| H2 | 695 mm | |

| L | 235 mm | |

| K | 430 | |

| T | 135 mm | |

| weight | 30.000 kg | |

| NPK No. 411 | ||

| NPK No. 412 | ||

| Availability | assembly time | |

| N842100002 | ||

| DN1 | 100 mm | |

| DN2 | 100 mm | |

| Outlet lateral left | ||

| Outlet lateral right | 2" | |

| H1 | 105 mm | |

| H2 | 695 mm | |

| L | 235 mm | |

| K | 430 | |

| T | 135 mm | |

| weight | 30.000 kg | |

| NPK No. 411 | ||

| NPK No. 412 | ||

| Availability | assembly time | |

| N842125001 | ||

| DN1 | 100 mm | |

| DN2 | 125 mm | |

| Outlet lateral left | 2" | |

| Outlet lateral right | ||

| H1 | 105 mm | |

| H2 | 695 mm | |

| L | 235 mm | |

| K | 430 | |

| T | 145 mm | |

| weight | 32.000 kg | |

| NPK No. 411 | ||

| NPK No. 412 | ||

| Availability | assembly time | |

| N842125002 | ||

| DN1 | 100 mm | |

| DN2 | 125 mm | |

| Outlet lateral left | ||

| Outlet lateral right | 2" | |

| H1 | 105 mm | |

| H2 | 695 mm | |

| L | 235 mm | |

| K | 430 | |

| T | 145 mm | |

| weight | 32.000 kg | |

| NPK No. 411 | ||

| NPK No. 412 | ||

| Availability | assembly time | |

- BLS® is a registered trademark of Duktus Rohrsysteme Wetzlar GmbH, D-35576 Wetzlar

Design

- Cast inlet elbow, flange/BLS® socket

- Can be shortened to suit the height

- Delivery incl. bolts, nuts, washers and insulating sleeves

Material

- Inlet bend and dual-chamber flange: GGG 40

- Coating: Epoxy coating acc. to RAL GSK

- Clamping ring: Delrin (POM)

- Screws: INOX A2

Installation and assembly

- Shorten spigot end on the bottom edge of a groove to the necessary extent. Treat the cut surface with the epoxy coating repair kit (Hawle Nr. 5293). Set white clamping ring with chamfer facing downwards in the groove. Pull rubber cuff over the spigot end. Mount hydrant and connect flange, including insulating sleeves.

more