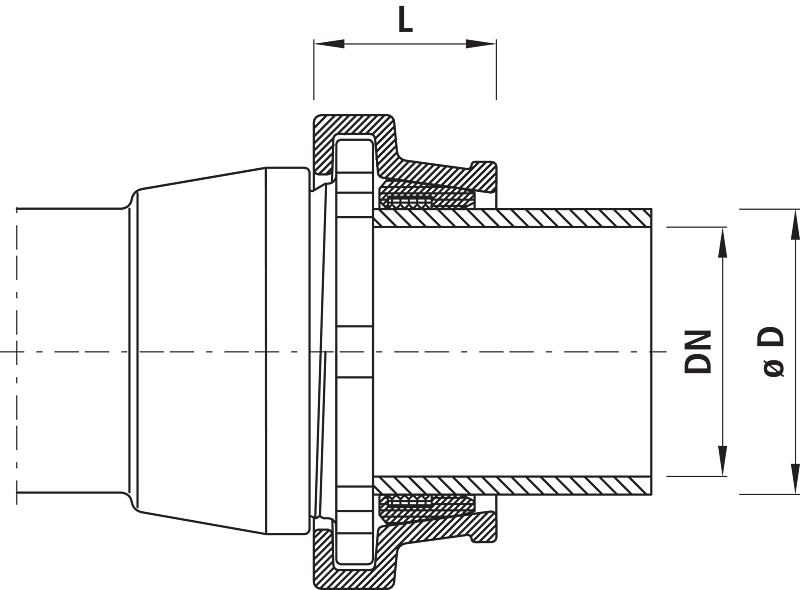

| Article No. | DN | ø D | PN (bar) | L (mm) | weight (kg) | NPK No. 411 | NPK No. 412 | Availability | watchlist |

|---|---|---|---|---|---|---|---|---|---|

| 5800080000 | 80 | 98 | 16 | 85 | 3.500 | 228818 | 228821 | ex warehouse | |

| 5800100000 | 100 | 118 | 16 | 90 | 4.000 | 228819 | 228822 | ex warehouse | |

| 5800125000 | 125 | 144 | 16 | 100 | 4.500 | 228821 | 228823 | ex warehouse | |

| 5800150000 | 150 | 170 | 16 | 100 | 6.000 | 228822 | 228824 | ex warehouse | |

| 5800200000 | 200 | 222 | 16 | 110 | 8.000 | 228823 | 228825 | ex warehouse |

DN

watchlist

| 5800080000 | 80 | |

| ø D | 98 | |

| PN | 16 bar | |

| L | 85 mm | |

| weight | 3.500 kg | |

| NPK No. 411 | 228818 | |

| NPK No. 412 | 228821 | |

| Availability | ex warehouse | |

| 5800100000 | 100 | |

| ø D | 118 | |

| PN | 16 bar | |

| L | 90 mm | |

| weight | 4.000 kg | |

| NPK No. 411 | 228819 | |

| NPK No. 412 | 228822 | |

| Availability | ex warehouse | |

| 5800125000 | 125 | |

| ø D | 144 | |

| PN | 16 bar | |

| L | 100 mm | |

| weight | 4.500 kg | |

| NPK No. 411 | 228821 | |

| NPK No. 412 | 228823 | |

| Availability | ex warehouse | |

| 5800150000 | 150 | |

| ø D | 170 | |

| PN | 16 bar | |

| L | 100 mm | |

| weight | 6.000 kg | |

| NPK No. 411 | 228822 | |

| NPK No. 412 | 228824 | |

| Availability | ex warehouse | |

| 5800200000 | 200 | |

| ø D | 222 | |

| PN | 16 bar | |

| L | 110 mm | |

| weight | 8.000 kg | |

| NPK No. 411 | 228823 | |

| NPK No. 412 | 228825 | |

| Availability | ex warehouse | |

Application

- For all makes of screw socket fittings/screw socket tubes and plastic-coated cast pipes DIN (Ecopur)

- Die Schraubmuffe ist für folgende Rohrarten geeignet:

Gussrohre:

- Mit Standard-Schraubringgarnitur: Schraubring, Konusring, Dichtring; Schubsicherung (Nr. 5800) aussenliegend

Ecopur-Gussrohre:

- Mit Standard-Schraubringgarnitur; Schubsicherung (Nr. 5800) aussenliegend:

PE-Rohre:

- Mit PE Anschweissende (Nr. 4523 und 4524)

Characteristics

- Operating temperature

- max. 40 °C - Pressure PN 16

Material

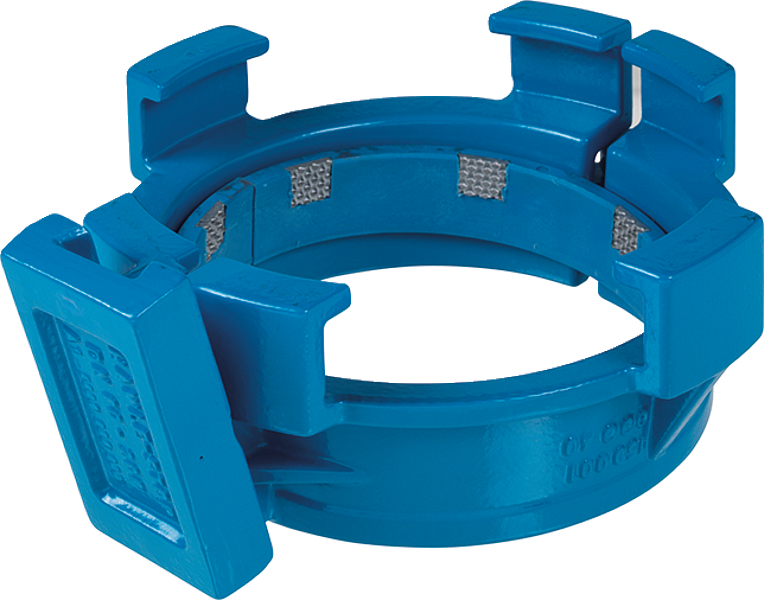

- Stops and wedges: GGG 40

- Hinge pins: Stainless steel

- Tapered clamping ring of PA

- Corpo:

- Ghisa sferoidale EN-GJS-400 (GGG 40)

- Rivestimento in EWS secondo GSK, RAL-GZ 662, spessore dello strato mit. 250 μm

Caution

- The cover lever must be pushed onto the pipe prior to assembly. There is a risk of breakage if fitted retrospectively.

more